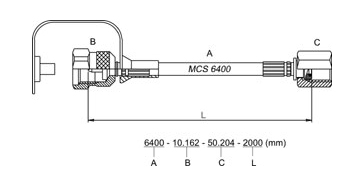

Description

|

|

|

... defines a complete range of hydraulic miniature

fittings, check couplings and accessories. MCS offers a simple, inexpensive

means to check pressure in hydraulic systems. Permanently mounted pressure

gauges and shut-off valves are no more necessary, thereby reducing initial

costs. Replacement costs due to gauges broken by system problems or external

damage are also eliminated.

MCS check couplings can be installed at any point of the hydraulic system

where pressure is to be monitored. For remote or hard-to-reach locations, an

MCS bulkhead coupling and an MCS micro-bore hose bring pressure to a central

panel thus simplifying its control. The micro-bore hose is so small and

flexible that it can be installed like electrical wiring.

Pressure can be checked while hydraulic systems are at full pressure. Micro

test fittings and micro-bore hoses can bear a max. working pressure of 630

bar. Thanks to their design, both the connector and the micro hose coupling

can be joined under pressure by screwing the coupling with two fingers

without any tools and any leakage; the connection is self-sealing and will

not loosen under vibration or pressure peaks.

MCS offers optional hose ends to adapt to many other test couplings from

other suppliers. Besides, they can be used for obtaining fluid samples from

various points in hydraulic systems or as an air bleed device.

The "Mini Control System" is versatile enough to be used instead

of rigid pipes for pressure gauges, pressure switches, pressure transducers,

pilot lines, etc.

It dampens pressure peaks and prevents vibration from reaching the

instruments, thanks to the micro hose's capillary effect.